Vials

Tougher, Cleaner, and Ready for Demanding Applications

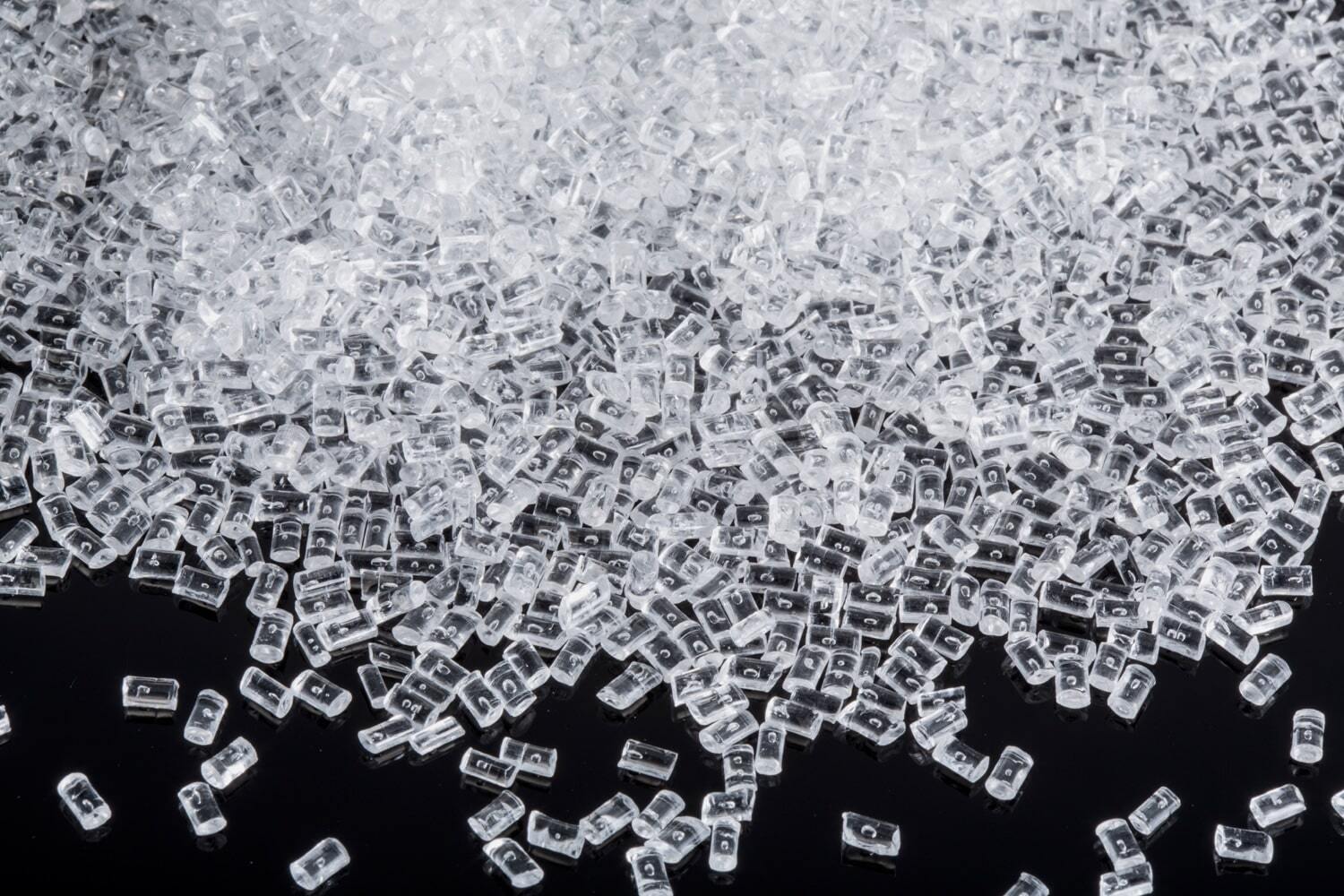

ZEONEX® and ZEONOR® resins, made of Cyclo Olefin Polymer, are durable and have very low impurities, preserving sample integrity over a wide range of storage conditions.

ZEONEX® and ZEONOR® Cyclo Olefin Polymers

Medical-grade Polymer Resin Delivers

Zeon's Cyclo Olefin Polymer (COP) enables vials with exceptional strength over a range of storage conditions, along with low moisture permeability and low risk of contamination from extractables and leachables. Medical-grade resins ZEONEX® 690R, 790R, 5000 and ZEONOR® 1020R have been assessed for compliance with USP Class VI and <661.1>, ISO 10993, in addition to JP and EU standards. Drug master file information available upon request.

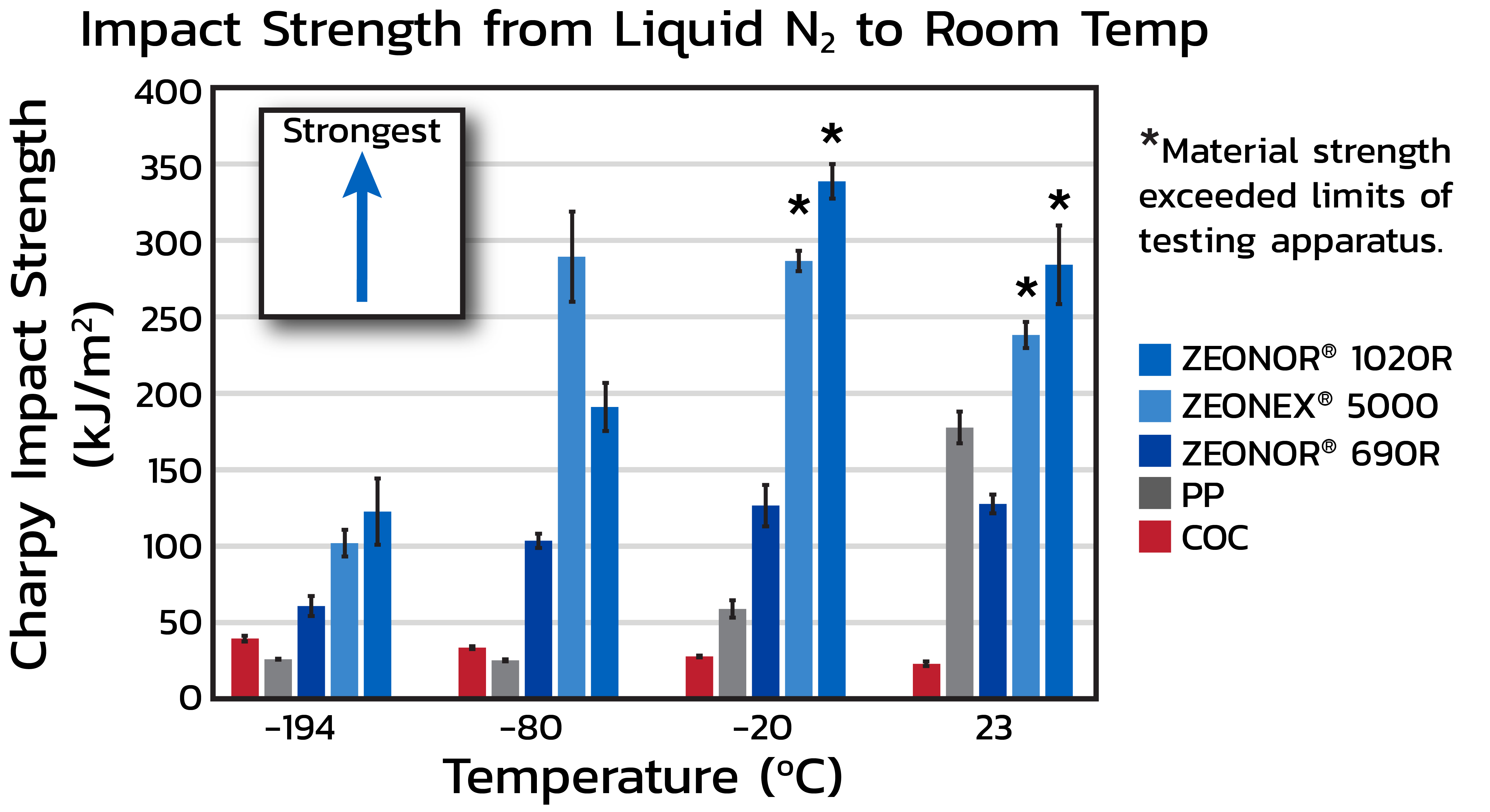

Durability

ZEONEX® and ZEONOR® Cyclo Olefin Polymer (COP) provides drop and impact-resistance for Pharmaceutical primary packaging. Vials made of ZEONEX® and ZEONOR® exhibit superior impact strength compared to glass and maintain impact strength even at cryogenic temperatures (-194 oC). There is little to no change in ZEONEX® and ZEONOR® mechanical properties post-sterilization.

Inert and Non-Reactive

Moisture Permeability

Sterilization

*Grades ZEONEX® 690R and 790R are compatible with steam/autoclave sterilization.

Industries

Precision Polymer for Unmatched Performance

We’ve got what you need – premium resins that power innovation, support compliance and improve product performance for major companies in Pharma, Medtech, research, and Diagnostic sectors.

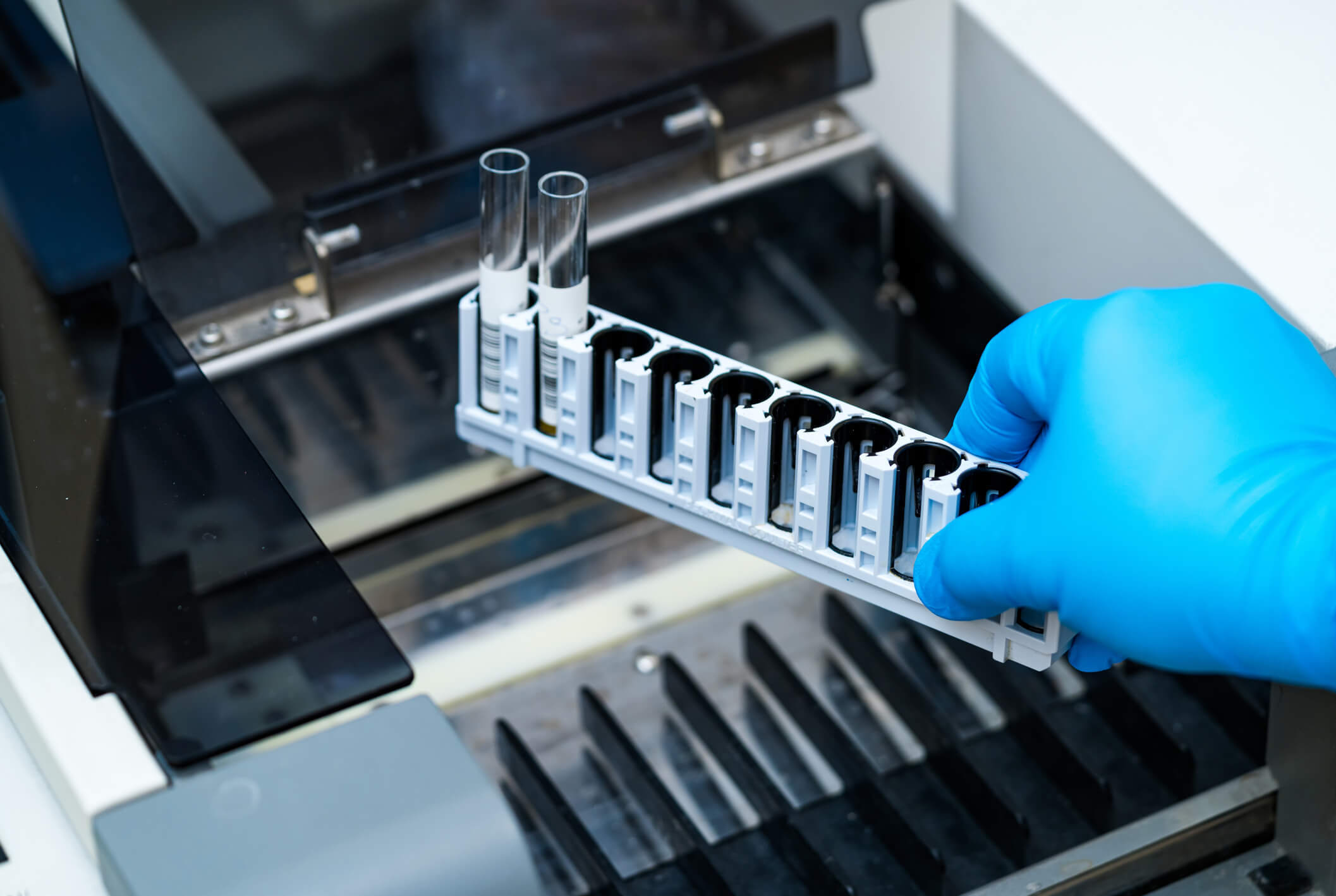

Pharmaceutical Primary Packaging

Life Sciences

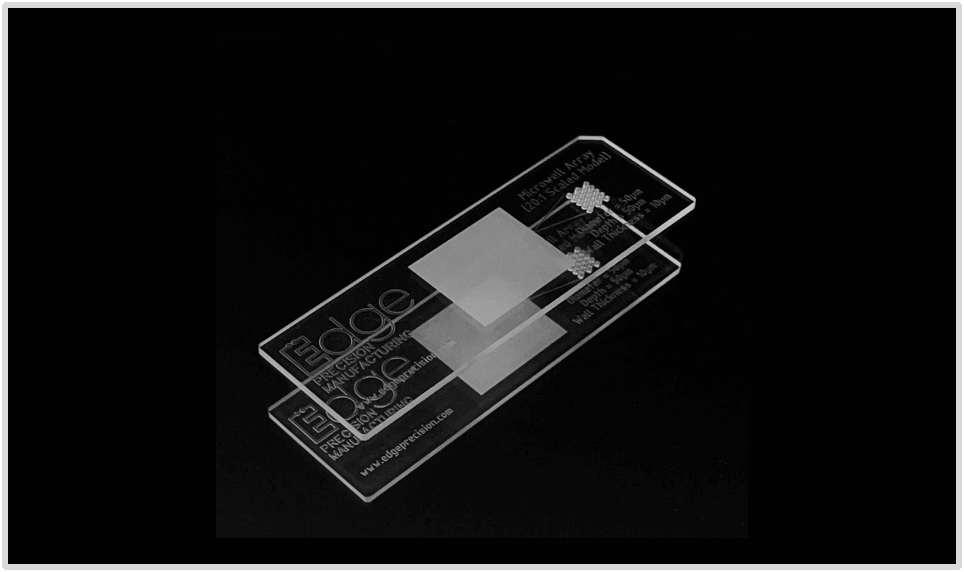

Diagnostics and Microfluidics

Contact Us

Partner with Experts

Our team goes beyond the sale to provide informed, technical solutions. Let us guide your innovation.

Start Your Project