Uncompromising Material for Demanding Applications

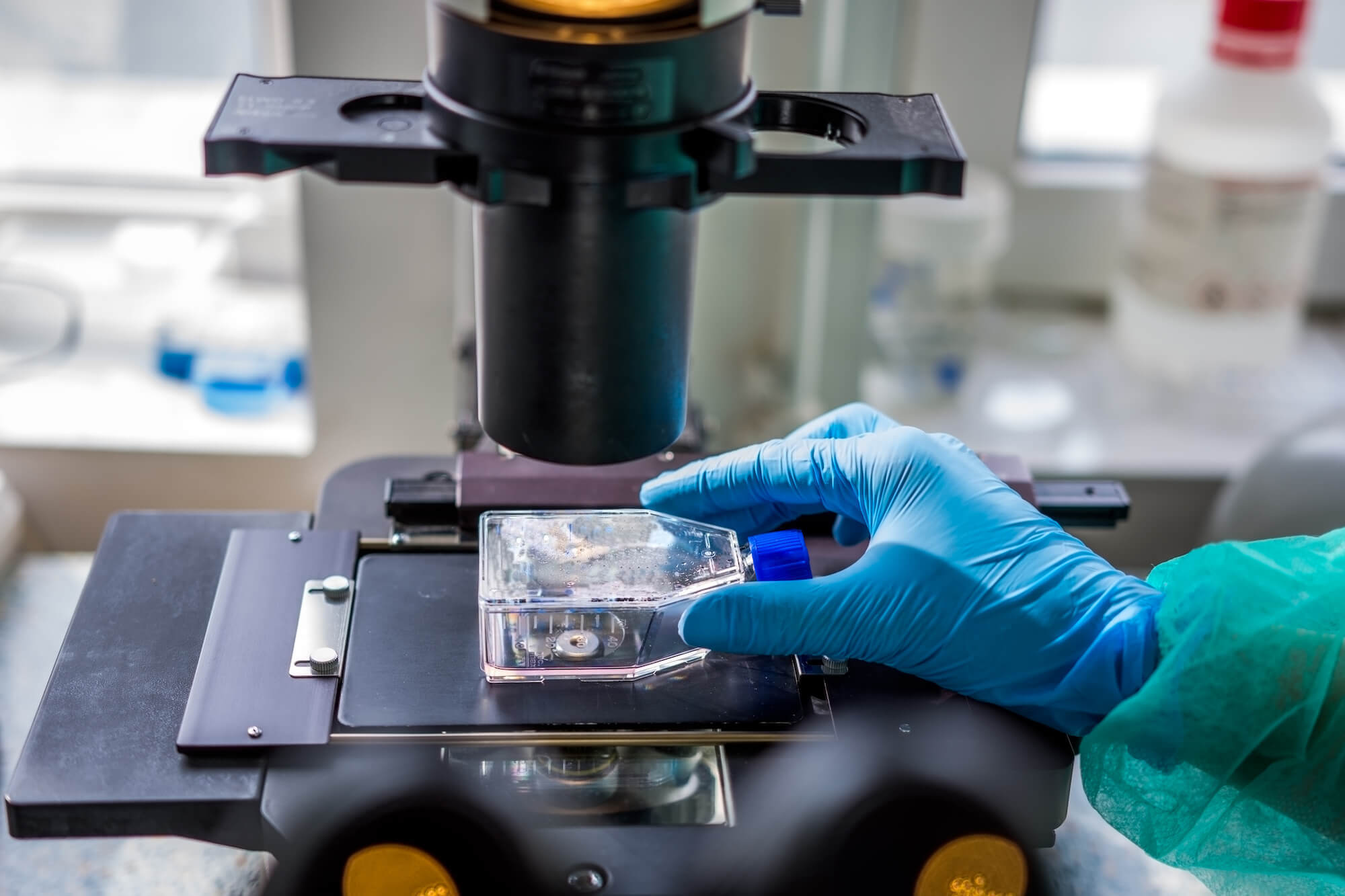

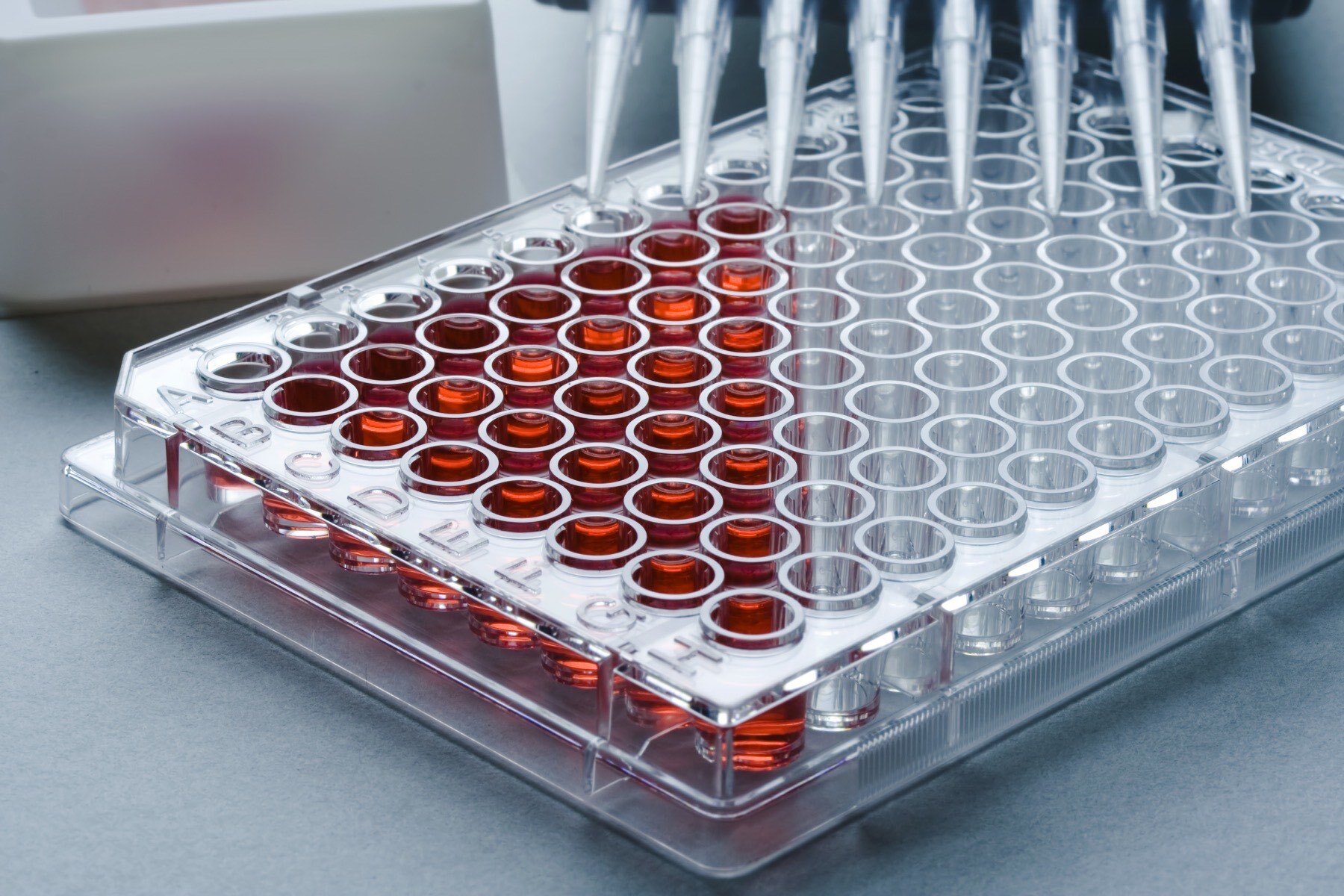

ZEONEX® and ZEONOR®, our high-performance resins made of Cyclo Olefin Polymer, deliver industry-leading results, enhancing products across medical, life science, automotive, and electronics fields.

New Standards for High-Performance Polymer

ZEONEX® and ZEONOR® Cyclo Olefin Polymer (also known as Cyclic Olefin Polymer or COP) resins offer glass-like transparency, low moisture permeability, and high mechanical strength, making them suitable for many industries and applications.

- Hydrophobic (surface energy 26 mN/m)

- High Purity

- Break Resistant

- Glass-like Transparency (>91% from 400 to 700 nm) with Low Haze

- Low Protein Absorption

- Sterilization Compatibility (Steam, Et0, Hydrogen Peroxide, Gamma)

- Non-Halogen

- Excellent Moldability

- Low-Temp Heat Sealing (Tg = 68.9 oC, ZEONEX®5000)

- Low-Auto Fluorescence

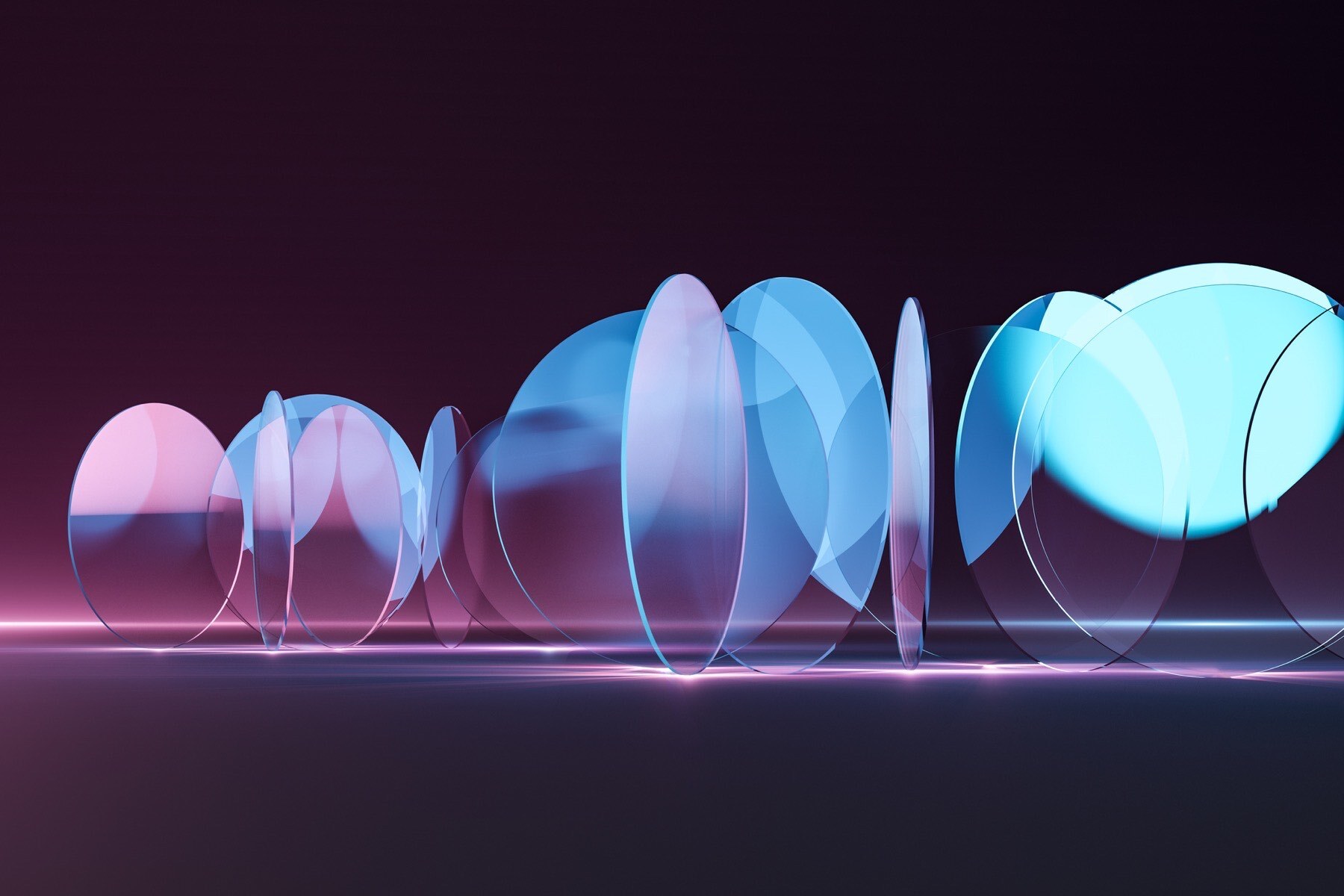

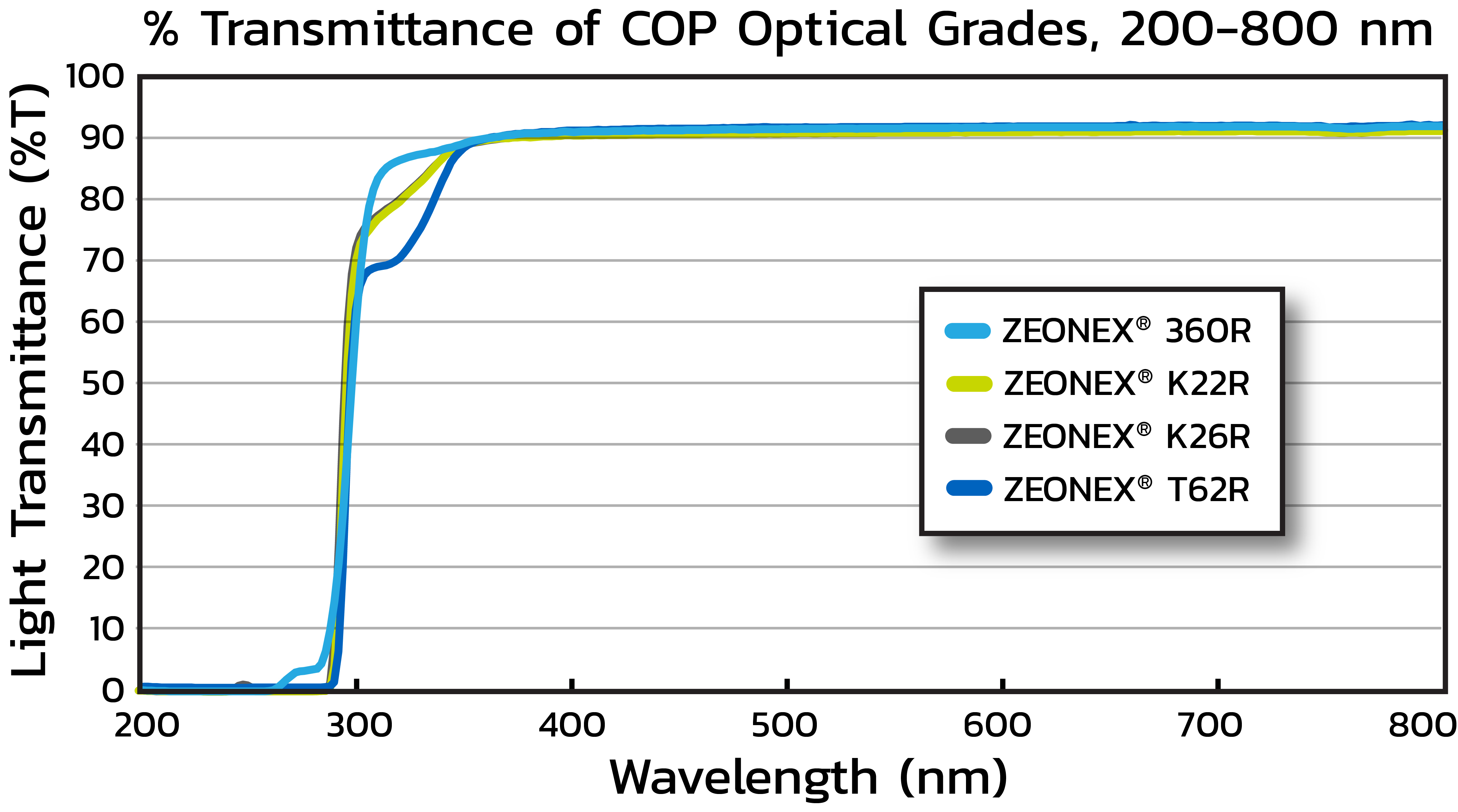

High Optical Clarity

A hallmark of all Zeon Cyclo Olefin Polymer (COP) resins is the high transparency across a range of wavelengths (> 91% between 400 – 700 nm). Zeon's optical grade COP resins also feature low birefringence and other features tailored for optical applications.

Durability

Low Moisture Absorption

Moldability

Production Capacity and Supply Chain Integrity

In mass production since 1990’s and globally adopted across Life Sciences, Optical, Consumer Electronics and Automotive Industries, Zeon's Cyclo Olefin Polymer (COP) has become the material of choice when quality matters and performance is critical. Zeon has met the growing demand for COP through numerous expansions of its manufacturing facilities and careful management of the supply chain.

Capacity for Any Sized Project

Supply Chain Integrity

Quality and Compliance

Innovation

Grades for Your Industry Sector

ZEONEX® and ZEONOR® Cyclo Olefin Polymer (COP) resins offer clarity, durability, and versatility across demanding industries.

We Deliver Success

Zeon is the world’s largest producer of Cyclo Olefin resins. Our vertical integration and decades of expertise in C5 chemistries and high-value monomer distillation uniquely positions Zeon above the competition. We recognize the importance of supply chain diversification and currently produce ZEONEX® and ZEONOR® COP Resins at four different factories, with a 5th factory announced.

Capacity for Any Sized Project

Supply Chain Stability

Certifications

Contact Our Experts

Get Support and Information About COP

Our team goes beyond sales to provide informed, specialized COP solutions. Let us guide your innovation.

Start Your Project