Optical Grade Cyclo Olefin Polymer

High-Performance Resins Set the Bar for Demanding Optics

Our high-performance ZEONEX® resins, made of Cyclo Olefin Polymer, enhance optical performance from consumer electronic devices to automotive touch screens.

Optical Grade ZEONEX® and ZEONOR® Advantages

For over 30 years, ZEONEX® Cyclo-Olefin Polymer has been the premier optical polymer for glass replacement in precision imaging lenses. With unsurpassed high transparency , low haze, high moisture resistance, low birefringence and excellent molding capability, ZEONEX® can meet the demanding optical requirements of high-performance applications including mobile device camera lens, AR/VR wearables, and sensors.

- Low surface roughness

- Ultra-low moisture absorption

- Glass-like transparency

- High ABBE number

- Low birefringence

- Low haze

- Compatible with high-power NIR laser

- Precision moldable

- Coatable

Glass-like Clarity

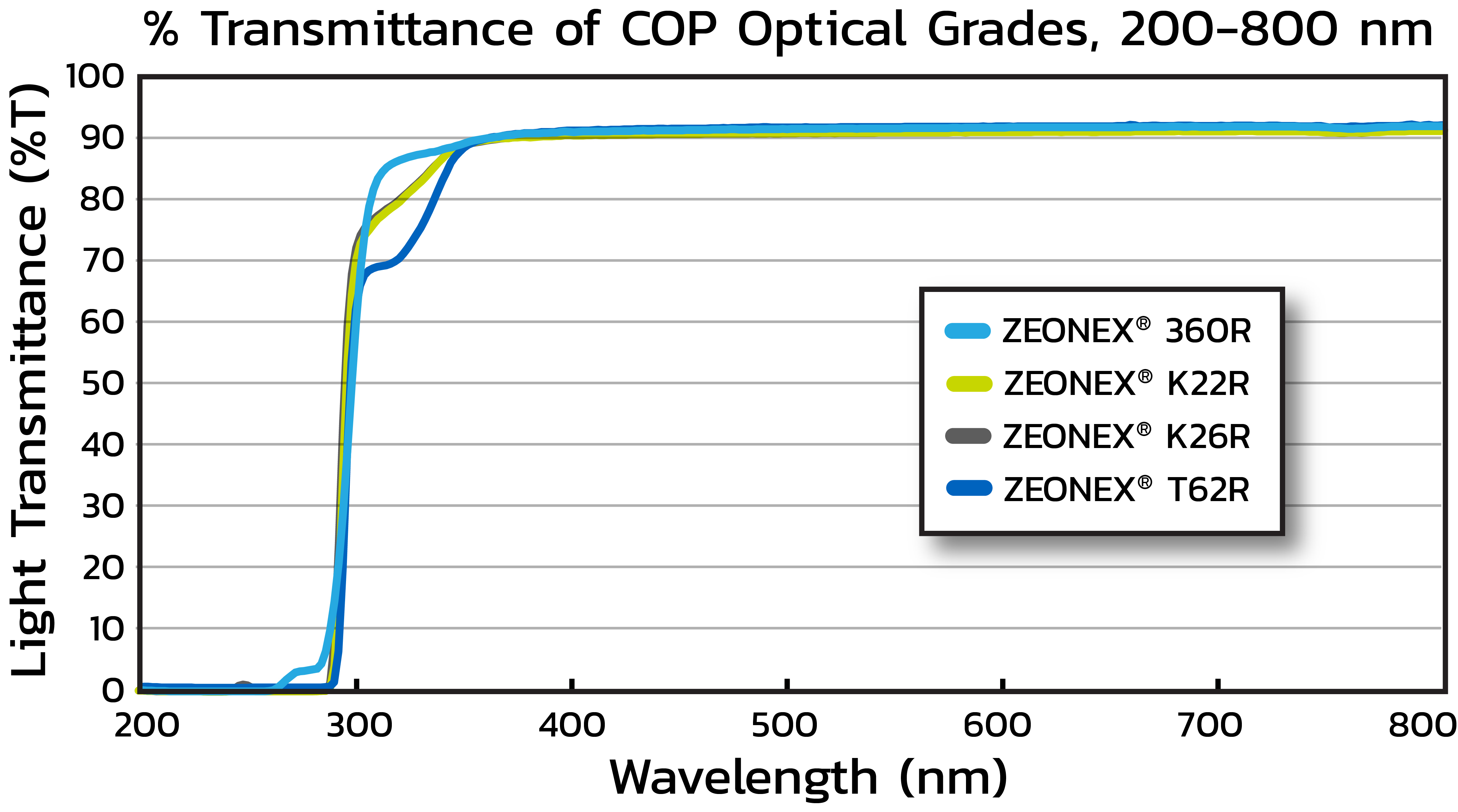

ZEONEX® COP offers >91% light transmission across UVA through NIR wavelengths. With a refractive index of ~1.53 and ABBE number of 56, ZEONEX® combines the optical characteristics of glass with the design freedom and cost-effectiveness of a molded plastic.

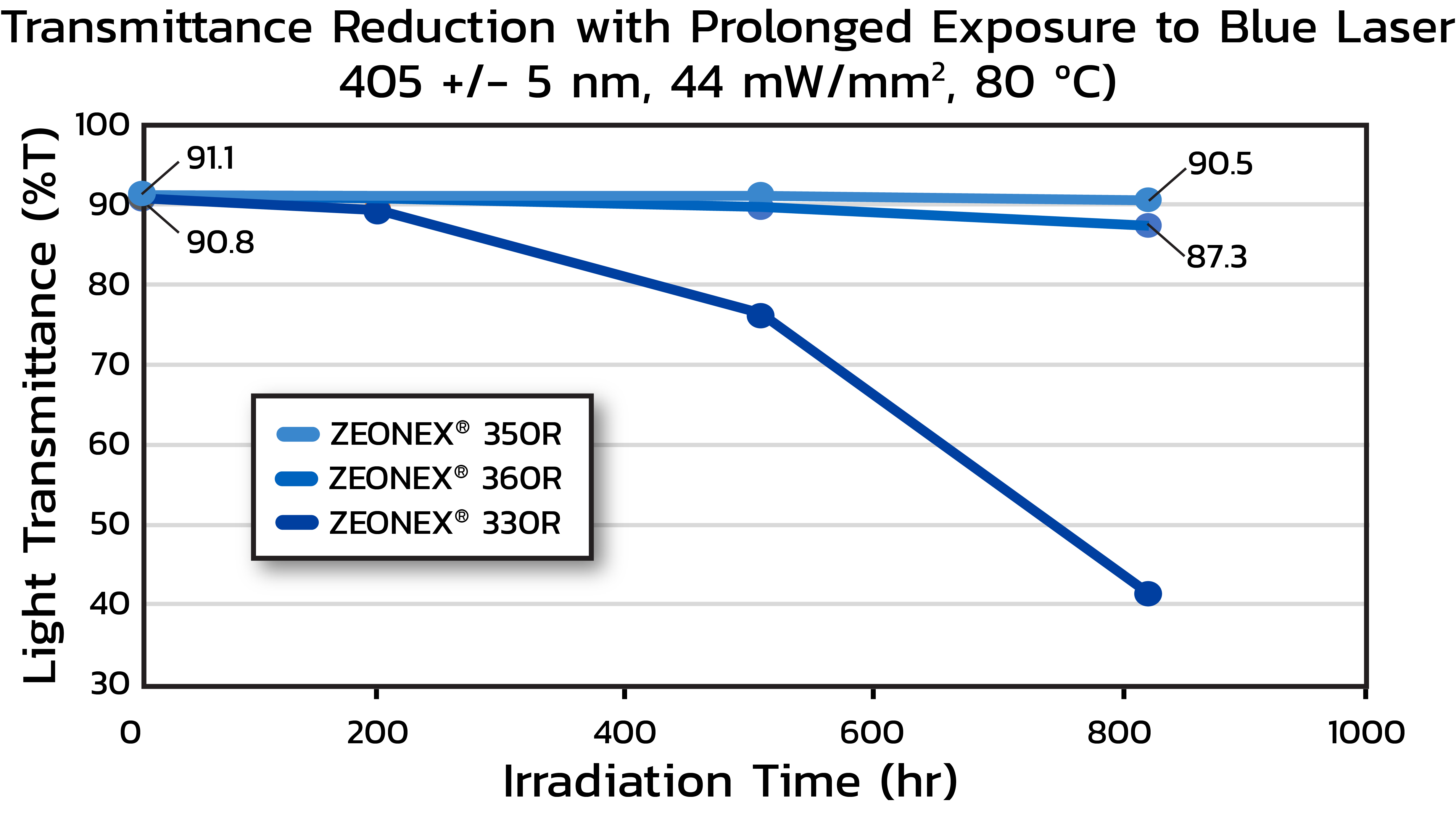

Blue Laser Capability

ZEONEX® optical grades are engineered to meet requirements of high performance and specialty applications. ZEONEX®360R offers superior resistance to long term, high intensity blue light wavelengths, with less than 4% change in transmission after 800+ hrs of irradiation at 400 nm.

Low Birefringence

Exceptional Moldability

Low Moisture Absorption and High Environmental Stability

Technical Highlights

| Property | Test Standard | Unit | ZEONEX® K26R | ZEONEX® K22R | ZEONEX® T62R | ZEONEX® 360R |

|---|---|---|---|---|---|---|

| Physical Properties | ||||||

| Melt Flow rate (280 ⁰C, 21.18 N) | ISO 1133 | g/10min | 52 | 32 | 16 | 18 (260 ⁰C) |

| Water absorption (23 ⁰C-sat) | ASTM D570 | % | <0.01 | <0.01 | <0.01 | <0.01 |

| Optical Properties | ||||||

| Refractive index | ASTM D542 | nd | 1.535 | 1.535 | 1.536 | 1.509 |

| Light transmittance | ASTM D1003 | % | 92 | 92 | 92 | 92 |

| Mechanical Properties | ||||||

| Tensile strength | ISO 527 | MPa | 54 | 72 | 67 | 37 |

| Tensile modulus | ISO 527 | MPa | 2530 | 2570 | 2650 | 2960 |

| Thermal Properties | ||||||

| Glass transition temperature | JIS K7121 | ⁰C | 143 | 143 | 154 | 121 |

Applications

Engineered to Perform

Smartphone Lenses

VR Lenses

Sensor Lenses

Certifications

Contact Us

Partner with Experts

Our team goes beyond the sale to provide informed, technical solutions. Let us guide your innovation.

Start Your Project