Optical Films

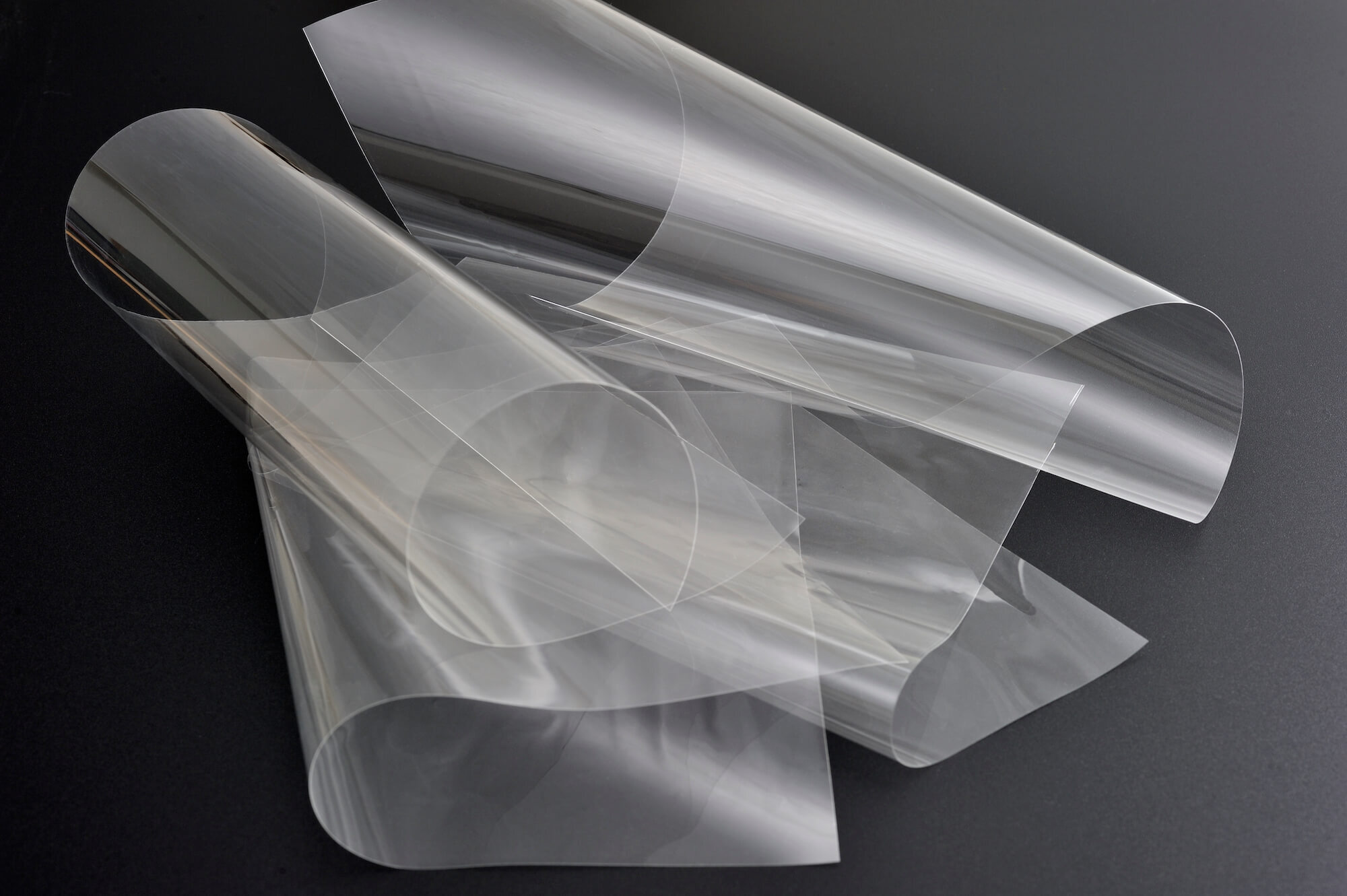

ZeonorFilm® combines ZEONOR® premium resin, made of Cyclo-Olefin Polymer (COP), with unique film processing technologies to achieve industry-leading optical clarity, durability, and performance for optical applications.

Clarity You Can See and Trust

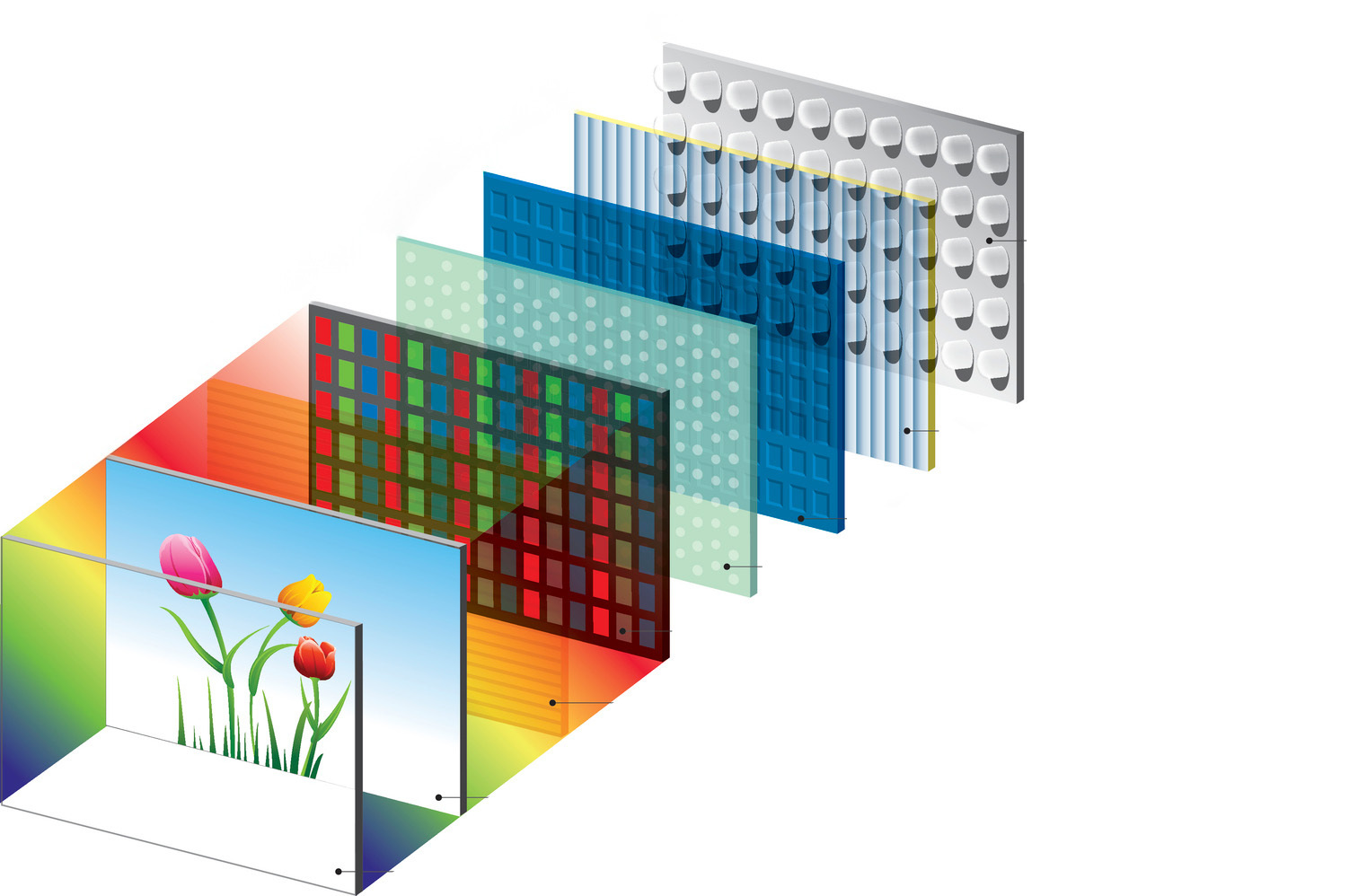

Designed for advanced display devices, ZeonorFilm® provides superior light transparency, ultra-low haze, and excellent stability in high temperature/humidity environments necessary for mobile devices (smartphone, tablets), AR/VR wearables, and TVs.

- Glass-like optical clarity

- Ultra low haze

- Availability as isotropic and ¼, ½ wave retardation films

- High heat resistance

- Low moisture or water adsorption

- Low outgassing

- Good chemical compatibility with acids/bases and alcohols

Glass-Like Clarity

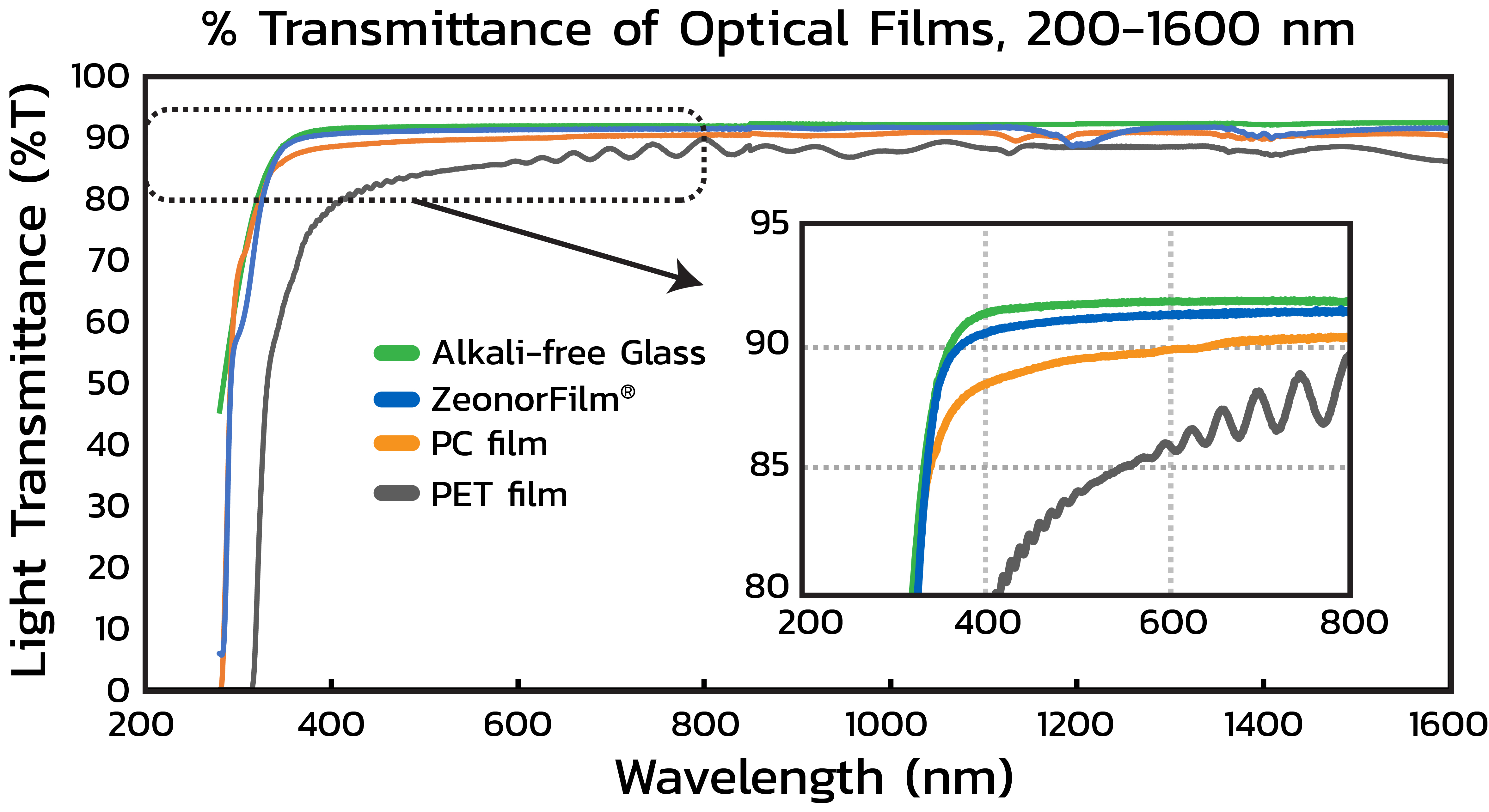

ZeonorFilm® delivers exceptional optical properties, with over 91% light transmittance and haze levels as low as 0.1%. It has higher transmittance over a wider range of wavelengths, with significant improvement in the 200-400 nm range.

¼ and ¼-wave Retardation Series (ZB-, ZM-, ZD-series)

Optional UV Cutoff

Isotropic ZF-series

Dimensional Stability

Chemical Resistance

Low Outgassing

Technical Highlights

ZeonorFilm® is available as isotropic (ultra-low birefringence) as well as ¼- and ½-wave retardation films.

| Property | Value | Unit | Test Method |

|---|---|---|---|

| Thermal Properties | |||

| Glass transition temperature | 140~170 | ℃ | Dynamic viscoelasticity measurement @ 1Hz,2℃/min. |

| Physical Properties | |||

| Specific gravity | 1.03 | ー | Fixed volume expansion method @ 25℃ |

| Water absorption | under 1 | % | JIS K 7209, ASTM D570 |

| Optical Properties | |||

| Refractive index | 1.53 | ー | Spectroscopic ellipsometry, reflected light @ 590nm |

| Light transmittance | 92 | % | Hazemeter |

| Retardation | <0.1 | % | AxoScan : 590nm |

| Mechanical Properties | |||

| Liner expansion coefficlent | 70 | ppm/℃ | TMA method @ 25~100℃ |

| Tensile strength | 70~80 | Mpa | No.8 dumbbell, 10mm/min |

| Tensile breaking elongation | 20~50 | % | No.8 dumbbell, 10mm/min |

| Pencil hardness | 3B | ー | Scratch hardness method (pencil) measured on a glass board |

| Dlelectric constant | 2.4 | ー | precision LCR meter @ 1MHz |

Certifications

Contact Us

Partner with Experts

Our team goes beyond the sale to provide informed, technical solutions. Let us guide your innovation.

Start Your Project